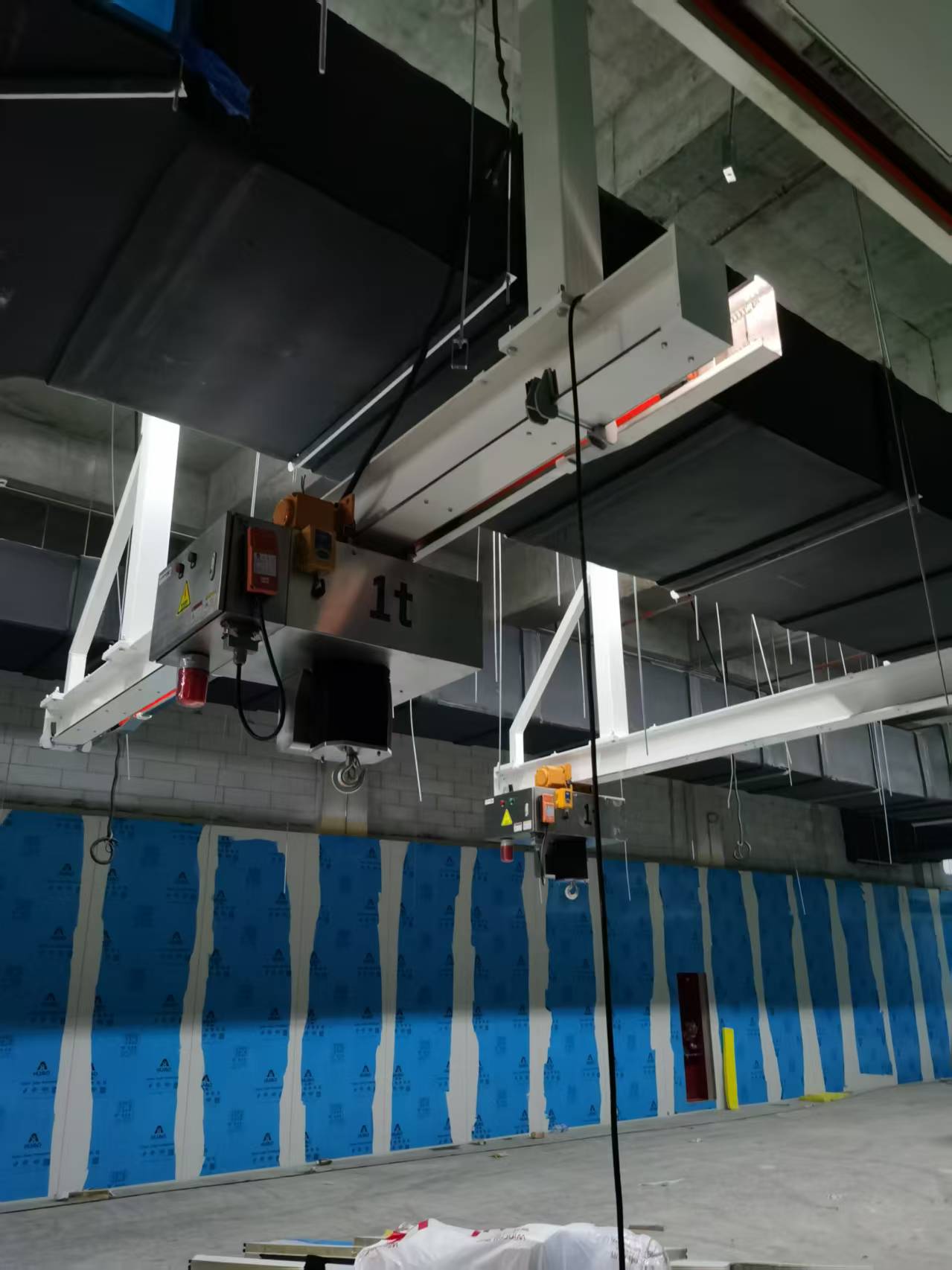

Single Beam Suspension Bridge Crane

Single girder suspension overhead crane features low headroom adaptability, smooth operation and flexible installation, suitable for assembly, maintenance, and short-distance material handling within workshops.

+86-15201969650

info@kfcscrane.com

No.5358 Huyi Road, Jiading District, Shanghai, China

The single beam suspension bridge crane consists of a bridge, end beams, operating mechanism, lifting mechanism and electrical control system. The bridge adopts a single main beam, which is suspended on the fixed crossbeam or integrated beam in the workshop through the end beams at both ends. No ground track is required, which greatly saves ground space. The lifting mechanism is usually an electric hoist or chain hoist, which can move horizontally along the main beam under the bridge to achieve full coverage of the working area.

Main structure and configuration of single beam suspension crane

● Main beam and end beam: H-shaped channel steel or aluminum alloy profile

● Lifting mechanism: electric wire rope hoist/electric chain hoist

● Traveling mechanism: double roller trolley

● Electrical control box: PLC+button box/remote control

● Safety device: travel limit, overload protection, emergency stop button

Design advantages of single beam suspension bridge crane

● Adopting H-shaped steel or aluminum alloy profile structure, it reduces the dead weight while ensuring the bearing strength and reduces the load pressure on the roof of the factory building.

● The H-shaped steel rail directly fixed on the top of the building does not require additional column support, freeing up ground space and facilitating equipment layout optimization.

● The standard span is 5~30 meters (can be customized), covering different plant layout requirements.

● The electric hoist stroke can match the workshop clearance height and support low space operations.

● The frequency conversion speed regulation and slow start/slow brake function can achieve ±10 mm precise positioning.

Typical application scenarios

● Production line assembly: In the assembly stations of the whole machine such as the body, engine, and gearbox, the workpiece can be accurately lifted and replaced.

● Inspection and repair: In the inspection, spraying or welding stations, parts can be quickly transported back and forth to improve work efficiency.

● Warehouse cargo distribution: Suitable for the loading and unloading operations of lightweight goods and turnover boxes to improve stacking density.

● Mold manufacturing workshop: hoisting and positioning of precision molds to avoid precision damage caused by manual handling.

The single beam suspension bridge crane meets the material handling needs in various industrial scenarios with its lightweight, land-saving, economical and flexible characteristics. Through reasonable selection, scientific installation and standardized maintenance, it will bring efficient, safe and low-cost production advantages to enterprises, and help the intelligent upgrade of workshops and increase production capacity. Click to contact us for customized solutions and quotes to meet your needs!