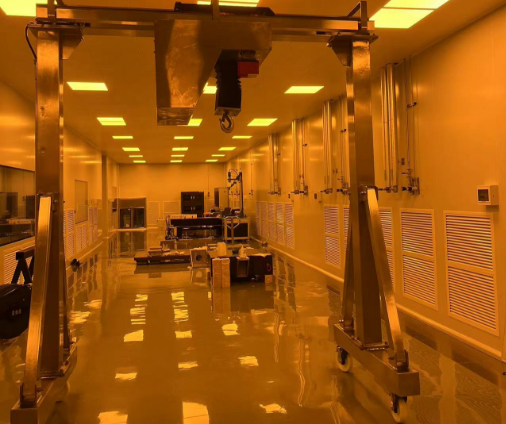

2 Ton Small Gantry Crane

The portable small gantry crane allows quick assembly, disassembly and height adjustment, suitable for light material lifting. Load capacity ranging from 100 kg to 2000 kg.

+86-15201969650

info@kfcscrane.com

No.5358 Huyi Road, Jiading District, Shanghai, China

The small gantry crane is a common lifting equipment with the ability of three-dimensional lifting operations. It is mainly composed of two columns and a beam. The lifting arm is installed on the beam, and the suspension and transportation of the goods are realized through the drive of the motor. The gantry crane made of stainless steel is a special gantry crane, has the characteristics of corrosion resistance and easy cleaning. Suitable for lifting operations in special industries such as food, medicine, chemical industry and electronics.

Stainless steel gantry crane is mainly made of stainless steel 304 or 316, which has excellent corrosion resistance, oxidation resistance, and high temperature resistance. Its structural principle is the same as that of ordinary gantry cranes, mainly composed of columns, beams, motors, lifting arms and other components. The difference is that stainless steel gantry cranes require special techniques and materials in the production process.

The specific configuration of the stainless steel gantry crane can be customized according to the needs of customers. Generally speaking, the main configuration includes:

Motor: The movement of the lifting mechanical arm is driven by the motor, so the motor is one of the core configurations of the stainless steel gantry crane. According to different working conditions and requirements, different power motors can be selected.

Suspension device: The suspension device is one of the core components of the lifting robot arm, which directly affects the flexibility and stability of the lifting robot arm. Generally speaking, the suspension device includes hooks, clamps, hangers and so on.

Control system: The control system includes the main control board, control cabinet, remote control, etc., which can realize the precise control of the lifting mechanical arm. Generally speaking, the control system should have flexibility, reliability and safety.

Safety devices: Safety devices include limit switches, overload protection devices, power failure protection devices, etc., which can ensure the safe operation of the lifting robot arm. Generally speaking, safety devices should comply with national standards and industry standards.

Stainless steel material: Stainless steel material is one of the core components of the stainless steel gantry crane, which has good corrosion resistance and high temperature resistance. According to different working conditions and requirements, different models and specifications of stainless steel materials can be selected.

Advantages of small gantry crane

Good corrosion resistance and adapt to harsh environmental conditions.

Easy to clean and will not pollute the production environment.

Made of stainless steel, high strength and stability.

The market price of small stainless steel gantry cranes varies according to factors such as brand, specifications and configuration. Generally speaking, the price ranges from USD 5,000 to USD 20,000, and the specific price is subject to evaluation based on the customer's actual requirements. Click to contact us for customized design solutions and product quotations.