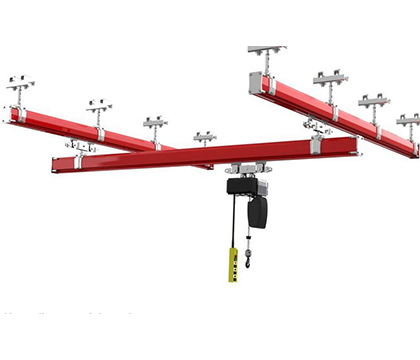

The aluminum alloy suspension crane is designed for the linear transportation of materials. It can connect loading and unloading stations directly, enabling round-trip and circular transportation operations. The crane can move along the track in any direction using various components such as straight rails, curved rails, turnouts, and turntables.

Aluminum alloy suspension cranes have found extensive application in the electronics industry due to their unique features and benefits. Here's how they are utilized:

Modular System Design

The aluminum alloy track is designed for easy operation and can be manually moved. The distance between the two ends of the track is very small, allowing for maximum space utilization.

The aluminum alloy suspension crane can be suspended from an existing workshop structure or roof without needing to support the crane track. The main beam and trolley of the crane are hinged, ensuring smooth operation without any obstacles. Additionally, the aluminum alloy crane has the ability to run on non-parallel tracks.

Move Heavy Load With Ease

With the aluminium light crane system, you can move heavy loads with ease. Our light crane systems are designed to move up to 2 tons, making them the perfect solution for many industrial applications.

Cleanroom Compatibility

Electronics manufacturing often takes place in cleanroom environments to prevent contamination. Aluminum alloy suspension cranes are well-suited for cleanroom conditions due to their non-corrosive properties. Unlike traditional steel cranes, aluminum alloy suspension cranes do not generate rust or particle contamination, ensuring a clean and sterile environment for electronic production.

Unmatched Precision

Our light crane systems are tailored to the individual requirements of our customers and offer high flexibility in handling materials. With our light crane system, heavy loads can be moved precisely and efficiently, which increases the working speed and reduces the wear of machines and tools.